- Investment

- 科学论坛

-

Program

News Message

Numerical Analysis of a Liquid Nitrogen Engine for Efficient Energy Conversion

- by wittx 2022-10-03

请输入您的信息!

1. Introduction

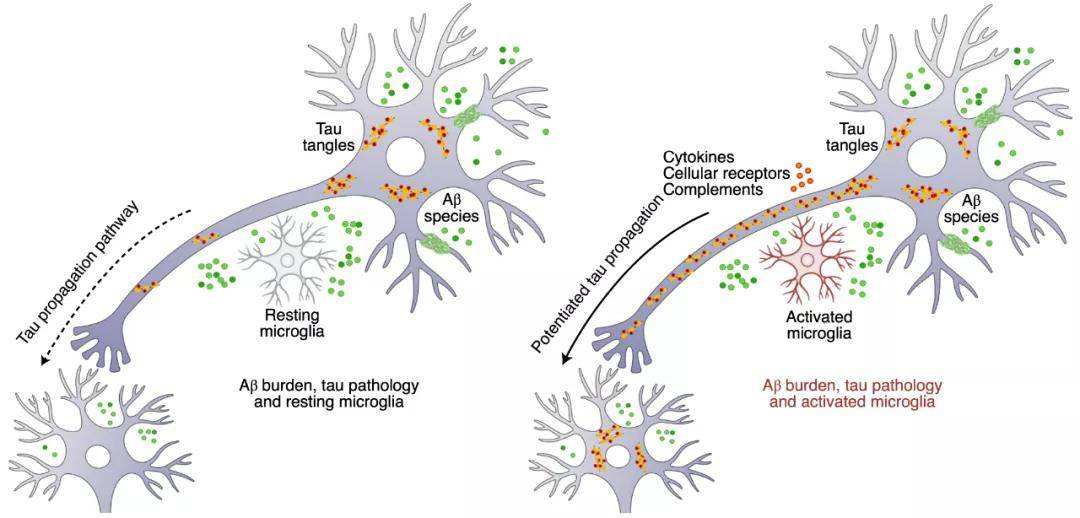

Awareness of the anthropogenic impact on the environment and its implications for climate change has increased, and there has been increasing pressure on governments and industries (in particular, the automobile industry) to reduce their carbon footprint. Regulations, such as the European Emission Standards, have sparked much research all over the world looking at ways to reduce exhaust emissions. (1−3) We still rely largely on fossil fuels. (4) The world’s transport sector is heavily dependent on petroleum. (5−7) Analysis of the global distribution of transport energy shows that 53% is used by light-duty (8) transport vehicles. Petroleum-based fuels are expected to be phased out over the next couple of decades, (9−11) recognizing the health hazards.Meanwhile, new emission limits set for the automobile industry, such as the EURO6 legislation, are considered to be a significant challenge for vehicle manufacturers and have led to high-profile manipulations of vehicle tests and engine control unit (ECU) settings. (12) Car manufacturers facing a $20 bn fine in the USA had to settle a buyback deal of 500 000 vehicles, costing them about $7.3 bn in April 2016. (13) In the current scenario, investment and research on alternative energy carriers is essential for all vehicle manufacturers.In 1998, in the U.K., a lower vehicle tax was introduced on diesel cars than petrol cars of the same size due to their better CO2 performance. People were given incentive to switch to diesel in 2001. (14) Later on, it was established that although diesel produces less CO2 than petrol, diesel engines emit tiny particles that penetrate the human lungs, brain, and heart, causing the death of more than 500 000 people (15,16) worldwide every year. Considering these facts, research for alternative low or zero-emission power sources was inevitable.The popularity and, hence, the production of hybrid and fully electric cars have significantly increased in recent years. Up to 3000 fully electric cars were being sold every month in the U.K. by May 2013; this figure increased to 5000 a month by March 2015. (17) A study analyzed that CO2 emission in Germany can be reduced up to 39% by replacing all conventional vehicles to electrical. (18) Nevertheless, barriers remain, such as high capital cost, battery technology, and well-to-wheel analysis.Liquid nitrogen (LN2) is produced by the separation/liquefaction of air, which is freely available in the atmosphere. The process involves the liquefaction of air by a cryogenic engine through the Joule–Thomson effect, (19,20) which is a change in temperature with the expansion of gas without producing any work or heat transfer. Cooling is generated as work is done to overcome the long-range attraction between farther apart gas molecules. The compression and refrigeration processes in the liquefaction can directly be powered by the mechanical work of the ocean or wind. LN2 production can be cheaper than that of hydrogen in terms of overall efficiency and capital costs as electricity conversion is not a part of the process. However, it is an energy-intensive process, which depends upon the plant scale for efficiency up to 60% and higher. (21) The size of the LN2 market is projected to grow from USD 12.48 billion in 2015 to USD 16.14 billion by 2020. Current driving factors of the market are the rise in demands for electronic products in developing countries and growing demands from the healthcare sector. (22) The LN2 consumption in vehicles may lead to saving in fossil fuels. (23)LN2 is used in various industries due to its very low temperature, low reactivity, and as being an energy carrier. (24) LN2 is used for freezing, preserving, and transporting food products. (25,26) It is also used for cryosurgery and cryotherapy for skin treatments such as removal of abnormal skin growth, (27) such as warts. Some other uses include quick freezing of water pipes to work on them, branding cattle, cooling materials for machining, etc. The use of LN2 as an energy carrier and its storage is discussed in detail in this paper.There has been research in several centers around the world toward making an LN2 engine to replace the use of fossil fuels. Most researchers considered evaporating LN2 with the help of heat exchangers to run the engine as a pressurized-gas-driven motor. (28,29) There was one exception where LN2 was introduced directly in a liquid form to run a turbine for power generation. (30)Prototype vehicles powered by LN2 were developed by three different universities. One used a pneumatic motor running after an air-powered heat exchanger. (31) The other two universities used vane-type motors and radial piston motors. (32) The LN2 consumption of all three experimental vehicles was very high. (33−35) A maximum speed of 39 mph, consuming 17.54 kg/m LN2 was observed. (36,37) Both of these experimental van-type vehicles had to carry a lot of equipment on board, occupying the rest of the van apart from the driver’s and passenger’s seats. (38)A theoretical comparison suggested that the working output of the cryogenic engine is slightly higher than that of a compressed-air engine (39) and it also runs cold. However, the externally evaporating LN2 engine is very inefficient and its LN2 consumption rate is high, even though LN2 has two and half times greater energy density than compressed air. Dye (40) proposed using a rotary power-coupled engine using an air-powered heat exchanger of a confined closed volume at an ambient temperature, increasing the pressure up to 350 bar. The equipment used to handle that high pressure is complex, making it a not very feasible system. Wang (41) suggested using a closed cycle Stirling engine together with a open-cycle conventional heat engine to achieve higher efficiency of the system with the same working pressure. Some other researchers suggested a multistage heat exchanger to improve the efficiency of the LN2 engine, (42) thus increasing the system complexity. A turbine system was produced where ambient air was drawn into the front of the turbine with the help of coupled fans that immediately evaporated and expanded the LN2 to run the turbine, generating electricity. This LN2 electric generator is currently being used in remote oil fields. (43)Storage of energy in the form of LN2 was first patented by Oxley four decades ago, where it was suggested as a way of storing energy during off-peak times and using it during peak times. (44) He suggested using a steam turbine running a Stirling refrigerator for converting air into liquid; on exit, the LN2 was evaporated in a series of air heat exchangers and turbines. Recently, “High view” developed a liquid air energy-storage system in Slough, U.K., where the system delivers back energy to the grid by utilizing industrial waste heat. The claimed efficiency of the system is 60–75% with a lifespan of 30–40 years. (45,46) A recent study suggested not only utilizing the stored energy but also using LN2 for the cooling requirements of buildings in hot weather (best suited for Gulf region countries). The study showed that up to 36% of energy can be saved, as compared to using conventional air conditioning systems. (47) There are a number of studies focused on improving the efficiency of the overall energy-storage system (48) by different methods.Research on the direct introduction of LN2 into the engine is the focus of the current study, and understanding on how quickly the LN2 can be expanded (i.e., evaporation rates), is important. In this regard, experimental investigations were found in the literature. The results concluded that a small droplet immediately creates very high pressure when injected into a water pool at room temperature. (49) It also showed the high speed of an LN2 drop in water of about 12 m/s when introduced in the form of an exposable capsule. Another experimental study showed that the evaporation spill rate of LN2 was up to 9.08 × 10–2 kg/s upon dropping on an unconfined concrete plate. (50) In a separate experimental study, the gauge pressure and the pressure rate increased to 284 and 500 kPa/s, respectively, when LN2 was injected into a water pool. (51) Although these models are not directly comparable with the current study, it was established that LN2 has the ability to evaporate and expand rapidly if suitable conditions are provided. In the case of an engine cylinder as an internal evaporator, it was assumed that 1000 rpm could be the maximum engine speed suitable for the LN2 engine.The food and beverage industries have been using LN2 injection for about four decades. Their system for injecting a small drop of LN2 has advanced over the years, and the latest injection systems can inject LN2 up to 2000 times per minute. (52) There are LN2 dosing systems currently being manufactured, capable of dispensing nitrogen in pure liquid form for preservation, pressurization, and freezing purposes. (53) The detailed investigation of all of the components used in the dosing system was helpful in understanding the potential application of LN2 for power generation in an engine.A simulation study on the LN2 engine was found in the literature where a two-stroke engine using LN2 was simulated using STAR-CD software. (54) The simulation study focused on the velocity field and the turbulent kinetic energy field of the LN2 engine. The simulation setup was based on the conventional LN2 engine system used by many researchers where LN2 is evaporated externally through a heat exchanger and supplied at 11 bar pressure to the two-stroke engine running at 1500 rpm. Results showed that the inlet velocity of the nitrogen gas into the engine was up to 250 m/s and at exhaust (just opened) up to 280 m/s, while the highest turbulent kinetic energy was found near the intake valve at the start of the intake phase. The highest temperature was observed at 20° CA, where the high-pressure nitrogen gas was just entering the engine. Another simulation study analyzed the LN2 storage system using a two-stroke reciprocating engine working on nitrogen evaporated with the help of a water heat exchanger. The results showed that the engine produced 2.2 kW with an inlet pressure of 20 bar. (55) The issue of low temperature is discussed following another experimental study. Experiments showed that the theoretical consumption of LN2 calculated as 24 g/s (56) is not practically possible with the evaporated LN2 engine. Most of the pre-evaporated LN2 systems discussed in the literature review faced seizing problems due to the low temperature inside the engine cylinder.A knowledge gap was found in the literature, with no studies of the potential for introducing LN2 in pure liquid form inside the reciprocating engine without any other source of heat apart from aspirated air in the cylinder. The current study focused on exploring the conditions required for the evaporation of LN2 inside the engine for efficient energy conversion and generating power from the expanded nitrogen gas inside the engine cylinder. It was established that if the right conditions are provided inside the four-stroke-type internal evaporation engine cylinder, the directly introduced LN2 can be evaporated and expanded for the generation of the power stroke. In the investigated system, there was no requirement for a separate heat exchanger. Analyzing the enthalpies of in-cylinder air and introduced LN2 for each cycle, the optimum combination was discovered to convert energy efficiently. In Section 3, with the help of computational fluid dynamics (CFD) simulation studies, the evaporation requirements and provision of these conditions are evaluated.In summary, there is an increasingly urgent need to develop a safe, pollution-free liquid automotive fuel. Hydrocarbon-fueled internal combustion engines emit CO2 and NOx, contribute largely to global warming, and cause serious atmospheric pollution, particularly in cities. These emissions can be palliated but are not eliminated by new technologies. H2-powered engines’ exhaust is mainly water vapor, with no CO2, but H2 engines too are not free from NOx emission. Electrically fueled vehicles cannot be recharged nearly as rapidly as liquid-fueled vehicles. The batteries they use are large, heavy, expensive, and contain elements (Li and Co) that are potentially in short worldwide supply.This paper considers the potential merits of a new type of liquid nitrogen (LN2)-powered automotive engine. LN2 engines have been developed in the past, but published designs have always used heat exchangers to gasify the LN2 before it enters the engine, thus wasting much of the energy stored in the LN2. They have, therefore, in effect been equivalent to compressed-air engines, and hence of low efficiency.The novel feature of the engine described here is that the LN2 is directly injected into the four-stroke cylinder in a liquid form (DI-LN2), and is rapidly evaporated by the heat of the compressed inspired air charge to produce the power stroke. The key insight here is that LN2 enthalpy is sufficient to do this in a DI-LN2 cycle, and produce useful external work. Some insight can be drawn into the likely characteristics of such an engine. LN2 production is already a large mature industry and could easily be scaled up further to meet the new market. The raw material is safe, abundant, and nontoxic. The compressors used should be powered by renewable energy sources such as solar, wind power, or waste (57) so their considerable thermodynamic losses would not be environmentally damaging.2. Numerical Methodology

ARTICLE SECTIONSThe engine-specific simulation software helps to evaluate, design, optimize, and study any change in fuel combination or engine design and supportive equipment. Simulation can provide very precise predictions of the output and consumption; however, it cannot take all variables and losses into account, and hence cannot be 100% accurate. Nevertheless, today’s industry and research rely heavily on simulation data before moving on to the experimental stage. Simulations are considered very important in modern engineering as they provide time and funding benefits prior to hardware experiments and help to optimize the experimental designs. The object of the simulations here was to study the behavior of the LN2 in the engine cylinder, including the evaporation process, and the variations in temperature and pressure found in a four-stroke cycle.2.1. Working Strokes of the LN2 Direct Injection Internal Evaporation (DI-IE) Engine

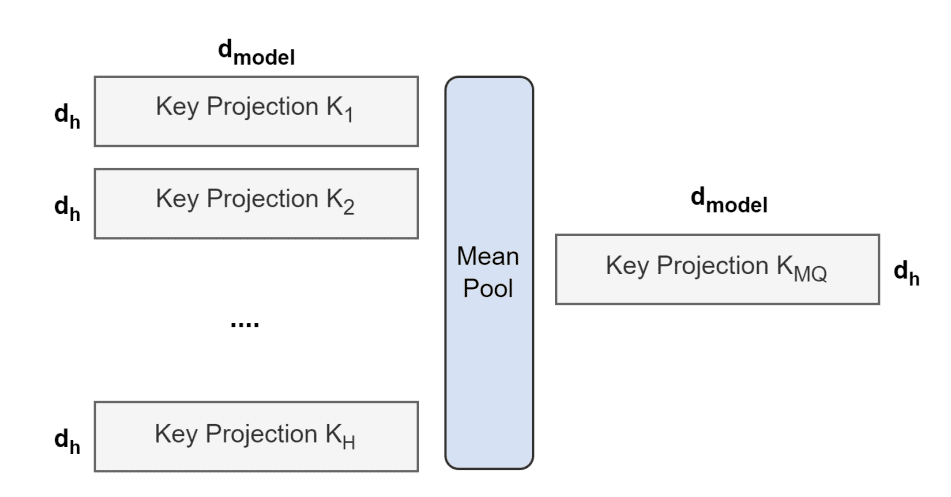

Similar to diesel and gasoline engines, in the first stroke, it aspires the air from the atmosphere. In the second stroke, it compresses the air, increasing its temperature. At the end of the compression stroke (top dead center, TDC), LN2 is introduced into the engine cylinder and evaporates immediately in the presence of hot air, generating the power stroke. The fourth and final stroke expels the air and nitrogen gas into the atmosphere by opening the exhaust valve. There is no combustion in any stroke, only evaporation of LN2 generating enough pressurized gas to overcome engine friction losses and to enable the intake and compression strokes along with output power. A schematic representation of the system under investigation is shown in Figure 1.Figure 1

Figure 1. Engine strokes and LN2 injection.

A hypothesis was developed that LN2 can be evaporated inside the cylinder with heat from the inducted air generated by the compression stroke. The power stroke generated by LN2 evaporation is then sufficient to overcome the compression stroke and mechanical losses to generate power for use. The hypothesis was inspired by the fact that LN2 expands about 700 times upon evaporation and it needs only ambient temperature and pressure for the evaporation process. In a four-stroke LN2 engine, the heat content of the air intake at the end of the compression stroke needs to be sufficient to provide evaporation conditions for a specific amount of LN2 in each cycle. It was, therefore, necessary to establish that this was the case, that LN2 evaporation delivers a sufficient power stroke, and that the temperature in the cylinder will recover for the next power cycle of the engine. All of these questions needed to be answered in the validation of the design concept.2.2. AVL Boost Platform

To analyze the DI-IE LN2 engine, the AVL Boost simulation software package was used. (58) AVL Boost is a fully integrated IC engine simulation software. It provides diverse models enabling accurate prediction of engine performance, exhaust emissions, and acoustics. The solution provides a comprehensive species transport with the flexibility of fuel consumption and working gas. It includes an internal solver for chemical reactions. (58) To predict the pressures, temperatures, indicated mean effective pressure (IMEP), power output, and other properties, AVL Boost “Virtual Engine Simulation Tool” software V2014 was selected. Different types of engines, including four-stroke, two-stroke, and pneumatic systems, can be simulated in AVL Boost. It optimizes simulation algorithms for engine elements.2.3. Governing Equations

The BOOST software package works as an interactive preprocessor, which prepares the input data for the main calculation program. Result analysis is provided by an interactive postprocessor. The main program provides optimized simulation algorithms for the available elements. The flow in the pipes is calculated as one-dimensional. Accordingly, the pressures, temperatures, and flow velocities provided by the solution of the gas dynamic equations are the mean values over the cross sections of the pipes. The flow losses at particular locations in the engine due to three-dimensional effects are calculated by appropriate flow coefficients.The results may be compared to the results of measurements or previous calculations. The animation presentation of the calculation results can be generated (59) to visualize the simulations. The properties of a gas (such as heat capacity) are dependent on its temperature, pressure, and composition. Boost calculates gas properties for each cell at each time step, with instantaneous composition. It calculates the thermodynamic state of the cylinder using the first law of thermodynamics as per eq 4. (60)where (1)

(1) is the change of the internal energy in the cylinder,

is the change of the internal energy in the cylinder,  is piston work,

is piston work,  is fuel heat input,

is fuel heat input,  is wall heat losses, and

is wall heat losses, and  is the enthalpy flow due to blow-by. The variations of the masses in the cylinder are calculated from the sum of the in-flowing and out-flowing masses as per eq 2. (60)where mc is the mass in the cylinder, u is specific internal energy, pc is cylinder pressure, V is the cylinder volume, QF is fuel energy, Qw is wall heat loss, ∝ is the crank angle, hBB is the enthalpy of blow-by,

is the enthalpy flow due to blow-by. The variations of the masses in the cylinder are calculated from the sum of the in-flowing and out-flowing masses as per eq 2. (60)where mc is the mass in the cylinder, u is specific internal energy, pc is cylinder pressure, V is the cylinder volume, QF is fuel energy, Qw is wall heat loss, ∝ is the crank angle, hBB is the enthalpy of blow-by, (2)

(2) is blow-by mass flow, dmi is the mass element flowing into the cylinder, dme is the mass element flowing out of the cylinder, hi is the enthalpy of the in-flowing mass, he is the enthalpy of the mass leaving the cylinder, qev is the evaporation heat of the fuel, f is the fraction of evaporation heat from the cylinder charge, and mev is the evaporating fuel.In-cylinder heat transfer to the cylinder head, the piston and the liner are calculated as per eq 3. (60)where Qwi is wall heat flow (cylinder head, piston, liner), Ai is the surface area (cylinder head, piston, liner), αw is the heat transfer coefficient, Tc is gas temperature in the cylinder, and Twi is wall temperature (cylinder head, piston, liner). Engine friction is calculated as per the PHH model shown in eq 4. (61,62)

is blow-by mass flow, dmi is the mass element flowing into the cylinder, dme is the mass element flowing out of the cylinder, hi is the enthalpy of the in-flowing mass, he is the enthalpy of the mass leaving the cylinder, qev is the evaporation heat of the fuel, f is the fraction of evaporation heat from the cylinder charge, and mev is the evaporating fuel.In-cylinder heat transfer to the cylinder head, the piston and the liner are calculated as per eq 3. (60)where Qwi is wall heat flow (cylinder head, piston, liner), Ai is the surface area (cylinder head, piston, liner), αw is the heat transfer coefficient, Tc is gas temperature in the cylinder, and Twi is wall temperature (cylinder head, piston, liner). Engine friction is calculated as per the PHH model shown in eq 4. (61,62) (3)where FMEP is friction mean effective pressure, CS is a constant part, P is for the piston group, VT is for the valve train, AUX is for auxiliary components, and IP is for indicated power.

(3)where FMEP is friction mean effective pressure, CS is a constant part, P is for the piston group, VT is for the valve train, AUX is for auxiliary components, and IP is for indicated power. (4)

(4)2.4. Simulation Setup and Assumptions

The BOOST Gas Properties Tool was used to add nitrogen instead of conventional fuels in the standard software features. The maximum reversible work available for cryogenic LN2 was taken as 712 kJ/kg. (34,59) Introduction temperature of the LN2 was taken as 77.65 K and the heat of evaporation for LN2 was set to 199.18 kJ/kg. (63) The air/LN2 ratio was initially taken as “1”; however, the software autoadjusts and optimizes the air–fuel ratio combination. In the LN2 engine simulations, the gas properties for air are evaluated based on a perfect gas approach with a gas constant R = 287.0 J/(kg·K) and an isentropic exponent k = 1.4. (64) In the case of diesel and gasoline engine simulations, settings were applied such that at any location in the system, the gas properties are determined from the actual gas composition, pressure, and temperature. However, for the LN2 engine simulations, it was taken to behave as an ideal gas.2.5. Workspace Graphical User Interface

The workspace was designed following the design tree shown in Figure 2. The elements included in the model were an engine, cylinder, air cleaner, injector, system boundaries (2 pcs), plenums (2 pcs), junctions and restrictions (8 pcs), measuring points (8 pcs), pipes (18 pcs), and a monitor. The model was designed by connecting the elements with pipes in the working area in the required order.Figure 2

Figure 2. AVL Boost workspace design model.

2.6. Engine Parameters

There were several experimental tests carried out in the past on a Lister Petter engine at the University of Birmingham. (65) To relate to experimental data, the Lister Petter single-cylinder engine was selected for the purpose of theoretical calculations and simulations. The experimental data with diesel fuel was available to compare the performance of the same size engine with the introduction of LN2 instead of diesel. The main engine parameters are given in Table 1.Table 1. Lister Petter Engine Parametersparameter unit value number of cylinders 1 engine speed rpm 1000 bore mm 98.4 stroke mm 101.6 connecting rod mm 165 displacement volume cm3 773 compression ratio 15.5:1 The consumption and power output results were compared to those of diesel and gasoline engines of the same size. However, in contrast to diesel and gasoline engines, there is no combustion process in the LN2 engine. The error factor can be considered ±10% for simulation result values as compared to experimental data, as suggested in a previous study. (66)3. Results and Discussion

ARTICLE SECTIONSIn the following section, results for liquid nitrogen are compared with diesel and gasoline fuels. The IMPRESS Chart postprocessing tool is used for the analysis of global engine performance data and analysis of results over a crank angle.3.1. Comparison of Cylinder Temperature and Pressure

The peak temperature at every cycle was calculated with the help of the simulation. To evaluate the simulation temperature data, it was compared with the earlier diesel engine experimental study. The experimental study showed that the diesel engine (global) inside the cylinder had about a maximum temperature of 2273.15 K while running at 1000 rpm. (67) The peak temperature in the LN2 engine reached about 1000 K, as compared to 1900 K in diesel and 1800 K in gasoline engines in the simulation results. There was no combustion in the LN2 engine, only evaporation of the LN2. The simulation results for peak temperatures of all three types of engines are shown in Figure 3.Figure 3

Figure 3. Peak temperature after evaporation/combustion of the four-stroke IE/IC engine.

The peak temperature stabilized after a couple of cycles in the LN2 engine as compared to diesel and gasoline engines where equilibrium was achieved after about 15 cycles (Figure 3), This could be due to the simplicity of the evaporation process and the absence of any combustion products. The temperature variation within a cycle is shown in Figure 4.Figure 4

Figure 4. Temperature variation as per the crank angle of the four-stroke IE/IC engine.

The same simulation tool and settings have been used for the diesel engine, and given results are comparable with the experimental data. In an LN2 engine simulation, the temperature did not remain 1000 K throughout a cycle. The LN2 is being introduced at 77 K in every cycle, consequently, the temperature inside the cylinder decreases, and the variation within a cycle is shown in Figure 4.A minimum temperature of 285.73 K (12.58 °C) was recorded under crank angle 450° for the LN2 engine as compared to 333.38 K (60.23 °C) and 334.51 K (61.36 °C) for the diesel and gasoline engines, respectively. It is a significant piece of simulation data, which shows that the minimum temperature was near ambient at any time within the cycle, while the LN2 was introduced at 77.65 K and without provision of an external source of heat to the engine.The peak pressure is about 50 bar in the LN2 engine, as compared to 30 bar in diesel and gasoline engines at 500 rpm, shown in Figure 5. Greater peak pressure was obtained in each cycle of the LN2 engine due to the fact that at TDC after the LN2 introduction, the amount of air becomes about double in a very small volume; with the immediate expansion of LN2, the pressure increases considerably.Figure 5

Figure 5. Peak pressure after evaporation/combustion of the four-stroke IE/IC engine.

However, in LN2, the engine pressure drops immediately with the increase in the volume by the piston movement downward as there is no combustion in the process. Consequently, the pressure does not remain high throughout the power stroke. The high variation of peak temperature and pressure in the diesel and gasoline engines is observed. An experimental study discovered that although the air and fuel are well mixed and engine load is high, the variation in the early combustion is due to the flow situation in the locality of the spark plug. Moreover, the fluctuation in the early cycles could be due to the fluctuation in the fuel concentration. (68) In our case, it is due to the fact that software is trying to optimize the air–fuel ratio in the initial cycles. However, in the LN2 engine, there is no combustion but only evaporation, therefore results are different.Figure 6

Figure 6. Pressure variation as per the crank angle of the four-stroke IE/IC engine.

A minimum pressure of 0.70 bar and a maximum pressure of 49.62 bar were observed within a cycle for the LN2 engine. In the diesel and gasoline engines, the minimum pressures were 0.42 and 0.40 bar while the maximum were 30.31 and 29.93 bar, respectively.3.2. IMEP, Effective Torque, and Effective Power

The IMEP of the LN2 and diesel engines is achieved at about 4.3 bar, as shown in Figure 7. The results shown are at an engine speed of 500 rpm. The variation in IMEP by changing the engine speed is shown in the following section. Although the IMEP achieved is about 4.3 bar for all three engine types, the consumption by the LN2 engine is about 30 times higher by weight than the rest. This is not unexpected taking into account that the maximum reversible work available of LN2 is much lower (712 kJ/kg) as compared to the heating value of diesel and gasoline (42 800 and 43 500 kJ/kg, respectively) used in the simulation calculations.Figure 7

Figure 7. IMEP of liquid nitrogen and diesel engines of the four-stroke IE/IC engine.

The injected LN2 mass was significantly different in the LN2 engine. Some other parameters, like indicated torque, power, effective torque, and power are compared in Table 2. Diesel or gasoline engines are not used at such low speeds practically. However, a comparison is given to quantify the performance of the LN2 engine. The LN2 is limited to run up to about 1000 rpm due to the time required for the evaporation of LN2 in every cycle. Obviously, diesel and gasoline engines generate more power output at higher speeds and are more efficient at higher revolutions per minute. However, the comparison is given to maintain the same conditions for all engines.Table 2. Comparison Chart of LN2, Diesel, and Gasoline Enginesproperty units LN2 engine diesel engine gasoline engine IMEP bar 4.30 4.32 4.32 inj. fuel mass g/cycle 0.61 0.024 0.024 indicated torque Nm 26.44 26.55 26.56 indicated power kW 1.38 1.39 1.39 effective torque Nm 18.32 18.44 18.44 effective power kW 0.96 0.97 0.97 Simulations were carried out under different engine speeds for the LN2 engine. The variations of effective torque, IMEP, and power are illustrated in Figures 8,9, and 10. The effective torque has been calculated using eq 5. (59)The maximum effective torque of 22 Nm is obtained at an engine speed of 300 rpm and it decreases gradually above 400 rpm. At 1000 rpm, the effective torque is 13.67 Nm, whereas the diesel engine registered 18.47 Nm at the same speed. The IMEP of the LN2 engine was calculated in AVL Boost using eq 6. (59) The exhaust stroke IMEP cycle duration (CD) is calculated from 180 to 360°, whereas intake stroke CD is considered from 360 to 540°. (5)The highest IMEP is 4.90 bar at an engine speed of 300 rpm; at higher speeds, it gradually decreases. At 1000 rpm, the IMEP of the diesel engine was 4.31 bar, while it was only 3.52 bar for the LN2 engine at the same engine speed. The effective power is calculated using eq 7 in the simulations (59)

(5)The highest IMEP is 4.90 bar at an engine speed of 300 rpm; at higher speeds, it gradually decreases. At 1000 rpm, the IMEP of the diesel engine was 4.31 bar, while it was only 3.52 bar for the LN2 engine at the same engine speed. The effective power is calculated using eq 7 in the simulations (59) (6)The power increased with the increase in the engine speed of the LN2 engine. It increases from 0.18 kW at 100 rpm to 1.43 kW at 1000 rpm. The diesel engine, under same conditions, gained 1.93 kW at 1000 rpm. Although the three different engine types compared in this study have almost the same effective power at 500 rpm, shown in Table 2, the effective power in the LN2 engine started decreasing above 900 rpm engine speeds as compared to the internal combustion engines. It reaches its maximum (1.45 kW) at 900 rpm and then starts decreasing at higher speeds. The change in the effective power under different engine speeds is shown in Figure 10. It is due to the fact that at higher engine speeds, LN2 does not get enough time to evaporate for each cycle.

(6)The power increased with the increase in the engine speed of the LN2 engine. It increases from 0.18 kW at 100 rpm to 1.43 kW at 1000 rpm. The diesel engine, under same conditions, gained 1.93 kW at 1000 rpm. Although the three different engine types compared in this study have almost the same effective power at 500 rpm, shown in Table 2, the effective power in the LN2 engine started decreasing above 900 rpm engine speeds as compared to the internal combustion engines. It reaches its maximum (1.45 kW) at 900 rpm and then starts decreasing at higher speeds. The change in the effective power under different engine speeds is shown in Figure 10. It is due to the fact that at higher engine speeds, LN2 does not get enough time to evaporate for each cycle. (7)

(7)Figure 8

Figure 8. Effective torque of the LN2 engine with different speeds.

Figure 9

Figure 9. IMEP under different engine speeds for the LN2 engine.

Figure 10

Figure 10. LN2 engine effective power under different engine speeds.

The change of IMEP relative at different engine speeds was analyzed, and it was observed that in the engine speed in the range of 100–1000 rpm, the IMEP was greater at engine speeds 200 to 400 rpm from 4.81 to 4.33 bar, with the maximum of 4.9 bar at 300 rpm. In contrast to the uneven curve of the effective torque and the IMEP, the power gradually increased from a low speed up to 900 rpm; above that, it gradually fell. Simulations were also carried on two-stroke and four-stroke engines, with the addition of a turbo charge. In both cases, a negative IMEP was obtained. Accordingly, these options were not considered for further investigations.3.3. Efficiency of the LN2 Engine

The indicated efficiency found in the simulation for all types of the engine was calculated using eq 8. (59)The indicated efficiencies using AVL Boost software calculations for all three types of engines are shown in Table 3, under similar conditions at an engine speed of 500 rpm. The efficiency of LN2 is calculated using the energy density value of “712 kJ/kg” in the denominator, multiplied by the mass of LN2 in each cycle (0.62 g/cycle). Accordingly, the denominator in the LN2 engine is as follows (eq 9) (8)

(8) (9)Table 3. Efficiency Comparison of Engines

(9)Table 3. Efficiency Comparison of Enginesengine type efficiency (%) LN2 engine 62 diesel engine 14 gasoline engine 16 The efficiency of the diesel and gasoline engines is calculated by multiplying the lower heating value (42 200 and 43 500 kJ/kg, respectively) to the fuel mass in the denominator. The mass flow rate of diesel and gasoline engines is much lower as shown in the consumption optimization of the simulation software (eqs 10 and 11).diesel:

(10)

(10)gasoline:

(11)

(11)3.4. Liquid Nitrogen Engine Consumption

The consumption rate of directly introduced liquid nitrogen in the LN2 engine is significantly higher than that of a diesel or gasoline engine. The conversion calculation for the consumption of the LN2 engine in grams per minute and grams per hour is shown in Table 4. However, the proposed engine consumes much less liquid nitrogen when compared to the conventional externally pre-evaporated liquid nitrogen engine. Even so, in the LN2 engine, the weight of fuel used is 30 times more than for diesel and gasoline engines. The consumption of fuel in the diesel and gasoline engines is 0.02 g/cycle as compared to that of the LN2 at 0.62 g/cycle according to the simulation results.Table 4. Consumption Calculations for the LN2 Engineparameter units value engine speed [rpm] 500 cycles [cycles/min] 250 consumption/C [g/cycle] 0.62 consumption/M [g/min] 0.62 × 250 = 155 consumption/H [g/h] 155 × 60 = 9300 LPG vehicle fuel cylinders, of up to 160 L capacity, are being used in the U.K. market. (69) Accordingly, a similar volume of LN2 fuel supply can be carried in the vehicle. As the proposed LN2 engine consumes 9300 g/h (9.3 kg/h), 1 l of liquid nitrogen is equal to 0.808 kg. Accordingly, 9.3 kg of liquid nitrogen will be equal to 11.50 L, which should be sufficient for 13–14 h of the proposed engine running. The specific fuel consumption of the LN2 engine is calculated as 5.5 × 106 g/(kW h), which is considerably higher than a normal diesel or gasoline engine. However, the simulation results showed that the effective power, achieved by the LN2 engine, of 0.96 kW is similar to diesel and gasoline engines at certain speeds, although the fuel injection for LN2 is considerably higher as compared to diesel and gasoline engines.3.5. Energy Balance of the Internal Evaporation Engine

The energy balance was carried out of the internal evaporation engine as the control volume, which is surrounded by a control surface. The flow of energy from and to the engine was as follows (70,71)IN: air and liquid nitrogenOUT: brake power, exhaust loss, convection, and radiation to the surroundings.Accordingly, the first law equation for this control volume is given using eq 12.The energy supplied by LN2 is calculated by (eq 13) (12)where mf is the mass flow rate of LN2 and QED is the calorific value or available reversible work of LN2, which is taken at 712 kJ/kg. At the engine speed of 500 rpm, the mass flow rate is calculated as 155 g/min = 0.002583 kg/s and Qs = 1.8391 kJ/s (kW). It means that 1.8 kW energy goes through the internal evaporation engine to produce 1 kW power (Table 2, 0.96 kW). In the process of energy conversion, 0.8 kW energy is consumed, which is about 44% of the supplied energy.

(12)where mf is the mass flow rate of LN2 and QED is the calorific value or available reversible work of LN2, which is taken at 712 kJ/kg. At the engine speed of 500 rpm, the mass flow rate is calculated as 155 g/min = 0.002583 kg/s and Qs = 1.8391 kJ/s (kW). It means that 1.8 kW energy goes through the internal evaporation engine to produce 1 kW power (Table 2, 0.96 kW). In the process of energy conversion, 0.8 kW energy is consumed, which is about 44% of the supplied energy. (13)The overall efficiency of the whole process can be calculated by taking into account the required energy to convert nitrogen from gas to liquid. A conventional cryogenic air separation unit consumes 0.357 kWh/kg power to produced LN2. (72) Therefore, 3.2 kW energy is required to convert 1.8 kW of LN2 for the internal evaporation engine. This shows that 56% of energy is used in the production of LN2.

(13)The overall efficiency of the whole process can be calculated by taking into account the required energy to convert nitrogen from gas to liquid. A conventional cryogenic air separation unit consumes 0.357 kWh/kg power to produced LN2. (72) Therefore, 3.2 kW energy is required to convert 1.8 kW of LN2 for the internal evaporation engine. This shows that 56% of energy is used in the production of LN2.4. Conclusions

ARTICLE SECTIONSThe research was carried out with the help of the AVL BOOST simulation package to evaluate the behavior of LN2 after its introduction (in its liquid form) in a four-stroke internal evaporation engine and its impact on the engine power output. The main conclusions are as follows:1. The results revealed that LN2 was fully evaporated and expanded, leading to power generation, and sufficient effective power was achieved by the LN2 engine at certain speeds.

2. There was enough pressure created inside the cylinder and the temperature remained near or above ambient in the cylinder at all times.

3. The IMEP and effective torque of the LN2 engine also competed with those of fossil fuel (diesel and gasoline) engines at specific engine speeds. However, it decreased at higher engine speeds.

4. The indicated efficiency of the cryogenic engine was calculated as considerably high. In this engine concept, there should be very little waste heat in the exhaust.

5. The consumption of LN2 (by weight) was considerably higher as compared to fuel consumption in diesel and gasoline engines; however, it was much lower than that of the externally evaporated LN2 engines used in earlier experimental vehicles.

6. The overall efficiency for all of the processes including LN2 production and power generation through an internal evaporation engine is 31%.

In contrast to fossil fuels, there are no depletion issues for LN2 as it is abundant in the earth’s atmosphere in a gaseous state and can cheaply be converted into a liquid form using energy from any source (sea, river, or wind power). It was established from this study that the direct injection of LN2 into an internal evaporation engine concept is a feasible concept, and power can be generated for vehicle propulsion or to fulfill other energy requirements with a zero-emission engine. The use of the developed technology of the internal evaporation LN2 engine in light-duty vehicles could contribute toward reducing worldwide energy consumption in the transport sector. The LN2 vehicle with the zero-emission engine will also help to achieve the agreed mitigation for reducing emissions in the World Climate Summit 2015 in Paris. (73) Further research is needed to establish the practical viability of the LN2 direct introduction system in an engine.https://pubs.acs.org/doi/10.1021/acsomega.1c00582

Share Http URL: http://www.wittx.cn/get_news_message.do?new_id=1001

Best Last Month

Information industry by wittx

Electronic electrician by wittx

Information industry by wittx

Information industry by wittx

Information industry by wittx

Information industry by wittx

Information industry by wittxMIT Mirai: Robust Artificial Intelligence Tools To Predict Future Cancer

Information industry by wittx

Information industry by wittx

Information industry by wittxMethod for converting gravity force, spring force and force of permanent magnets in a rotary motion.